School of Medicine Cyclotron Building

Cyclotron / Laboratory

University of Pennsylvania

School of Medicine

Cyclotron Building

Philadelphia, PA

- Building Type

- New Construction on Existing Site

- Project Size

- 8,000 SF

- Year Completed

- Fall 2010

- Design / Project Team

- AHA Engineers

- Owner Representative / Contact

- David Pancoe

About

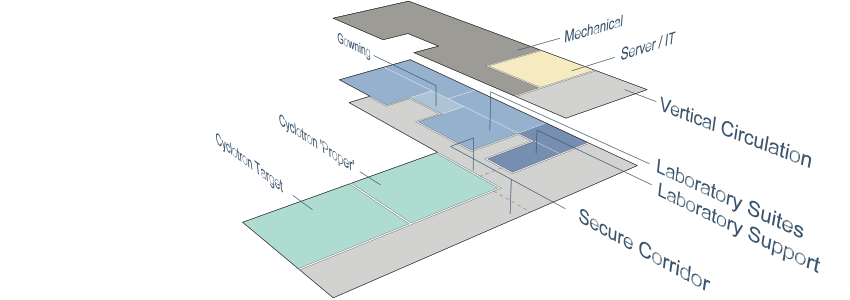

STPCx Commissioning and the University of Pennsylvania completed construction of a new Cyclotron and laboratories. This building was a major step for the university in reaching the goal of providing research capabilities second to none. The program of the building includes providing state-of-the art space for medical oriented research. The building includes the installation of a new cyclotron (cyclotron proper and target room), dry-bench laboratory suites, lab-support, research office space, and associated mechanical and electrical systems.

Near the middle of the design phase for the facility, the University identified that comprehensive building commissioning would help to ensure that their investment will perform as intended and meet the needs of the building users. Prior to this project, STPCx had limited experience with cyclotron equipment. We were retained by the University as an independent commissioning agent for the project in the fall of 2010.

Project

This Cyclotron expansion, except for the central utilities and exhaust system, does not share any equipment with the existing cyclotron and labs. The HVAC for the new project will provide a new non-re-circulating air handling unit, hot water heating loop, and glycol system preheat. The new cyclotron will be served by its own dedicated CHW loop, vacuum, and compressed air. The project scope includes the demolition of the southeast side of the existing plaza to accommodate the new cyclotron, target area and new lab suit. The extent of this work includes foundations, space protection, a new laboratory with laboratory equipment, HVAC, electrical, and plumbing equipment. Included in the new expansion are connections to central utilities, power, steam, CHW, and an upgrade to the air exhaust system that serves the existing and new cyclotrons.

Scope

Commissioning services were focused on maintaining and verifying that the conditions of critical equipment were stable and functioning.

Commissioning activities addressed:

- Testing and verification techniques for complex laboratory systems

- Bridging the gap between construction and functionality

- Verifying the pressurization

- Bridging the gap between TAB and BAS

- Avoided failures of critical systems

- Energy savings from commissioning

- O&M savings from commissioning

- Training building users and operators as part of commissioning process

- Lessons learned: scheduling and planning commissioning activities

- Valuable commissioning documentation

Commissioning Results

There were several critical issues discovered during the commissioning process. Shortly after we became involved in the project it was discovered that the pressurization was not designed correctly. In the event of a chemical accident in the lab spaces or corridors the potential for contamination and serious injury could affect the researchers and shut-down the facility for several weeks, costing potentially several thousands of dollars in lost revenue. Although the redesign of the system impacted the schedule, it was necessary to ensure the future safety of the occupants and functionality of the equipment to support the university’s research efforts.

Lessons Learned

Buildings with high performance conditions require accurate monitoring of pressure, alarms, exhaust ventilation, and specialized equipment. Laboratory and cyclotron buildings require a specific attention to detail that is far more sophisticated than the standard basis of design. In this particular project, the selected cyclotron manufacturer is from Belgium. In the design process the manufacturer required that the vacuum and compressed air be selected to coordinate with their equipment. The result was that the equipment was selected to be from a Belgian company. When the equipment arrived on-site it was manufactured for a European electrical current rather than the US Standard 480V. This could have been avoided if a CA, who specializes in submittal reviews and project delivery had been a part of the process and project team earlier.