School of Arts & Sciences Chemistry 1958 Renovation

Laboratory

University of Pennsylvania

School of Arts & Sciences

Chemistry 1958 Wing

Philadelphia, PA

- Building Type

- New MEP Infrastructure and Renovation of Existing Lab

- Project Size

- 9,000 GSF

- Year Completed

- Fall 2010

- Design / Project Team

- Perkins & Will AHA Engineers

- Contact

- Edward Benfold, AIA

Senior Project Manager

Overview

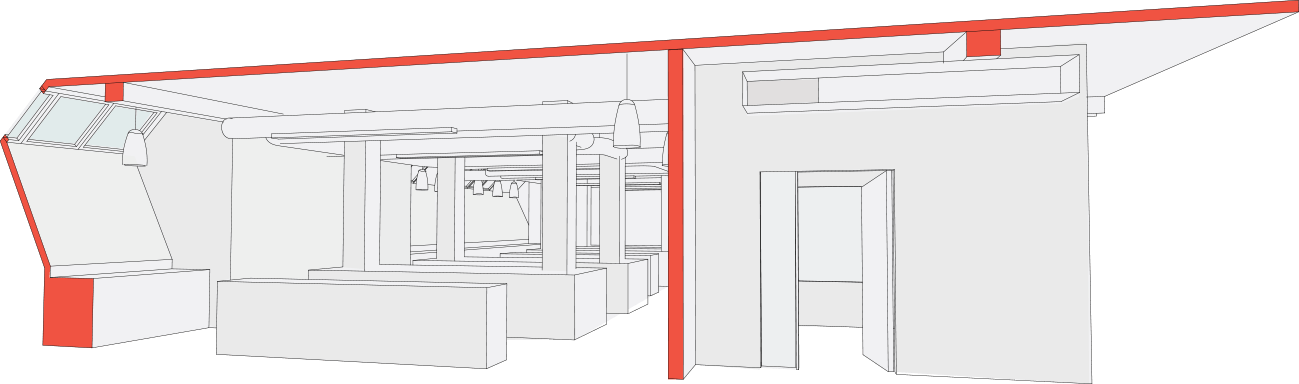

Our first priority with Chemistry 1958 Phase I and II was to establish an approach to ensure the building will be delivered to meet the specific needs of the University and its occupants – present or future. The scope of our attention offers an evaluation of building conditions and assistance to refine its performance. Participation from the owners, architects and project consultants contributed to a project that developed from the inside out, from the laboratory teaching environment to the impacts of the overall systems performance.

In 2009 the college of School of Arts and Sciences, in conjunction with the University of Pennsylvania Real Estate Services consulted STPCx to assist in the delivery of Phase I and provide solutions to issues raised during construction through Phase II. The first phase of the project focused on the installation of new MEP infrastructure to serve the first floor laboratory renovations. Phase I and II included a new full laboratory and funishings with all the services needed in a modern wet chemistry lab.

Aspects of Commissioning

The new renovation is one of the most advanced labs in the building thank in part to its dedicated ventilation and temperature controls systems for the optimizations of comfort and safety. Some aspects of teh design are very innovative, particularly details relating to possible contamination in the event of an accident. For example, the chemical prep-dispensing room is connected to the lab via a fume hood with sashes in both rooms tha act as a sally port between both spaces ensuring safe transport of chemicals between spaces. Other safety measures include bench level exhaust fans. Elimination of cross-contamination between the east and west laboratories is achieved by providing appropriate air pressure relation between the spaces.

Project

The HVAC system consists air handling unit with occupancy modes of in use and lecture in the labs, an energy recovery coil, glycol preheat coil, central chilled water coil, reheat water system, glycol heat exchanger, and high efficiency variable speed drives were installed on both fans and pumps. Phoenix valves with integral reheats temperature and ventilation controls maintain supply and exhaust air flows in the lab proper, prep–dispensing room, support office, and conference room; rendunant exhaust fans are located on the roof.

The commissioning process brought to light some simple adjustments to sensors and controls – many of which had never been installed properly. These relatively easy fices can lead to large energy reduction benefits and building managers can be more confident that the building is a lot easier to operate. To assure quality, STPCx spent a considerable effort to verify with Phoenix Controls and the TAB contractor to ensure that spaces were heating and cooling consistently and accurately, in both modes of operation. The spaces were balanced with certified equipment in accordance to NEBB standards to maintain quality.

Energy Conservation

The STPCx team, acting as the lead commissioning consultant for the project and was responsible to ensure that the design strategies implemented to improve the laboratory conditions and energy efficiency were achieved. Because the air handling unit is designed for one hundred percent outside air energy efficiency was an immediate concern. Reductions in energy include efficient lighting, lighting controls such as occupancy sensors, and scupper configuration that borrowed indirect natural light - resulting in a space with substantially improved lighting and control.

Lessons Learned

Largely due in part to the group effor between the commissioning agent, client, and construction team the laboratory renovation provides a high-quality and full functional teaching lab environment. At the beginning of the project STPCx met with the project team to define communication protocols, and to ensure that everyone understood the primary goals of commissioning. This with the regular participation in meetings and a consistent job site presence helped to build a cooperative and constructive working relationship among the team.

Several issues that were discovered, many were a results of installation responsibilities falling between specific equipment vendors and the subcontracted trades. Even with an experienced team, such as with the Chemistry 1958 renovation, issues can be often overlooked. Especially when known issues are concealed, communication breaks down between the hierarchies, or a high priority issue takes the precedence over less important problems. In this project, we realized the value in encouraging the team to raise issues during construction rather than at the end of the project. Having done so, it provided flexibilty and assurance that a reliable solution will be provided and have a lessened impact on the schedule and cost.

This experience feeds back into our commissioning process and has allowed us to more confidently make recommendations to our commissioning process and has allowed us to more confidently make recommendations to our clients and to increase their understanding of the important ramifications of decisions they will be making during project completion.

Commissioning Activities

- Reviewed documentation and submittals including equipment, controls, mechanical, electrical, etc.

- Developed commissioning plan including Prefunctional Checks and Functional Tests.

- Performed periodical site visits to verify quality and review installations.

- Attended construction coordination meetings to review progress and discuss procedures.

- Performed equipment review with specialized contractors and witnessed start-up.

- Oversight of TAB contractor and spot checked pressurization and space temperatures.

- Reviewed plumbing isolations and emergency functions, battery back-up and emergency failures.

- Assisted in resolving issues. Maintained a list of deficiencies and corrections follow-up.

- Ensured through functional testing that equipment, control points and swquence of operations meet the safety and design standards of the University.

- Oversaw training operation and performance procedures.

- Delivered a report detailing the process.

- Recommended project turnover.